At McCloskey & Company, we pride ourselves on knowing our products inside and out and developing great relationships with our equipment manufacturers. Recently, the entire team (Joe, Gene, & Molly), ventured to Missouri to visit fabrication facilities for 2 of our principals, Gilbert Industries and Houston Polytank. We thoroughly enjoyed our trip and will definitely be back!

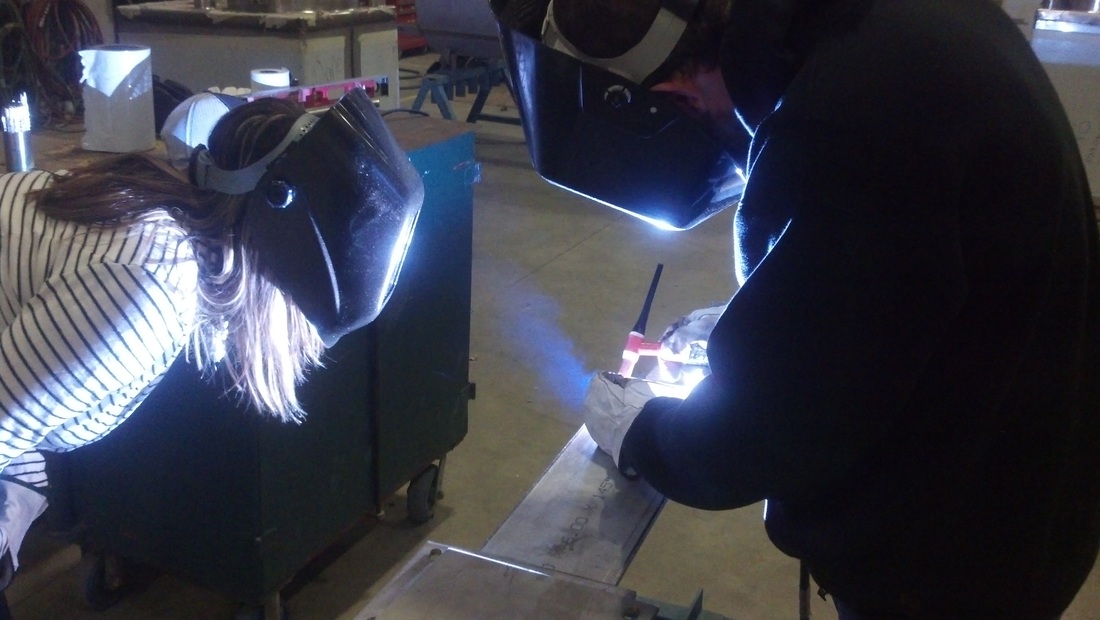

First up was a visit to the wonderful team at Gilbert Industries in Sparta, located just between Branson and Springfield. Gilbert is one of America's premier stainless steel and alloy vessel manufacturers. While Gilbert is renowned for their proprietary field tank erection system, they also have extensive shop tank capacity and know-how. All Gilbert shop-fabricated vessels are expertly welded, engineered in-house, and can also be customized to meet customers' individual needs and ASME/API code requirements. Our team was able to see this first-hand on our shop tour and extensive educational training with the Gilbert folks. As a family-run company, Gilbert's hospitality extends to employees as well as their representatives. Also, as an added bonus, Molly got to practice some amateur welding out in the shop (not to worry, they won't let her anywhere near an actual job site...yet!). Check out some pictures of our visit below:

First up was a visit to the wonderful team at Gilbert Industries in Sparta, located just between Branson and Springfield. Gilbert is one of America's premier stainless steel and alloy vessel manufacturers. While Gilbert is renowned for their proprietary field tank erection system, they also have extensive shop tank capacity and know-how. All Gilbert shop-fabricated vessels are expertly welded, engineered in-house, and can also be customized to meet customers' individual needs and ASME/API code requirements. Our team was able to see this first-hand on our shop tour and extensive educational training with the Gilbert folks. As a family-run company, Gilbert's hospitality extends to employees as well as their representatives. Also, as an added bonus, Molly got to practice some amateur welding out in the shop (not to worry, they won't let her anywhere near an actual job site...yet!). Check out some pictures of our visit below:

After Sparta, we headed north to Hopkins (about a mile from the Iowa border) to meet our new friends at Houston Polytank. This unique line provides corrosion resistant tanks with a new twist....plastic winding. Houston Polytank is the only supplier in the US of these one-of-a-kind vessels that combine the corrosion resistant benefits of thermoplastics with the strength and thickness of a wound tank, all at competitive pricing. Unlike traditional roto-molded plastic tanks, Houston tanks are much more robust and not subject to buckling or deformation. Houston Polytank manufactures tanks using polyethylene and polypropylene in sizes ranging from 5 to 50,000 gallons, which are ideal across many corrosive applications where plastic tanks have not traditionally been an option. During our visit, we were able to see this unique manufacturing process first-hand, as well as enjoy the hospitality of the knowledgeable and dedicated Houston Polytank team. Some highlights:

RSS Feed

RSS Feed